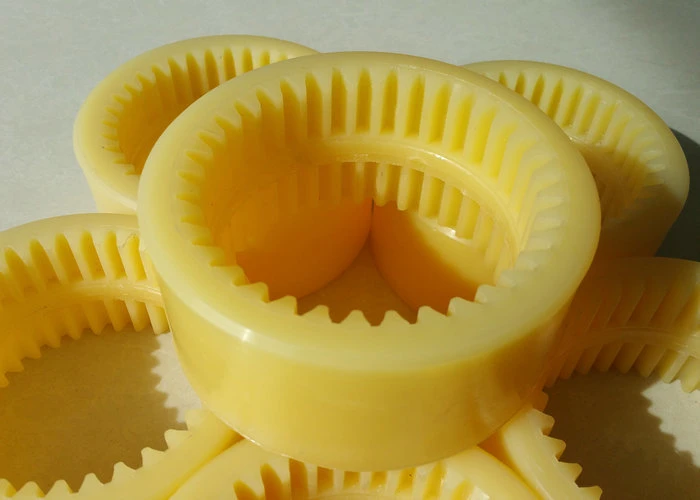

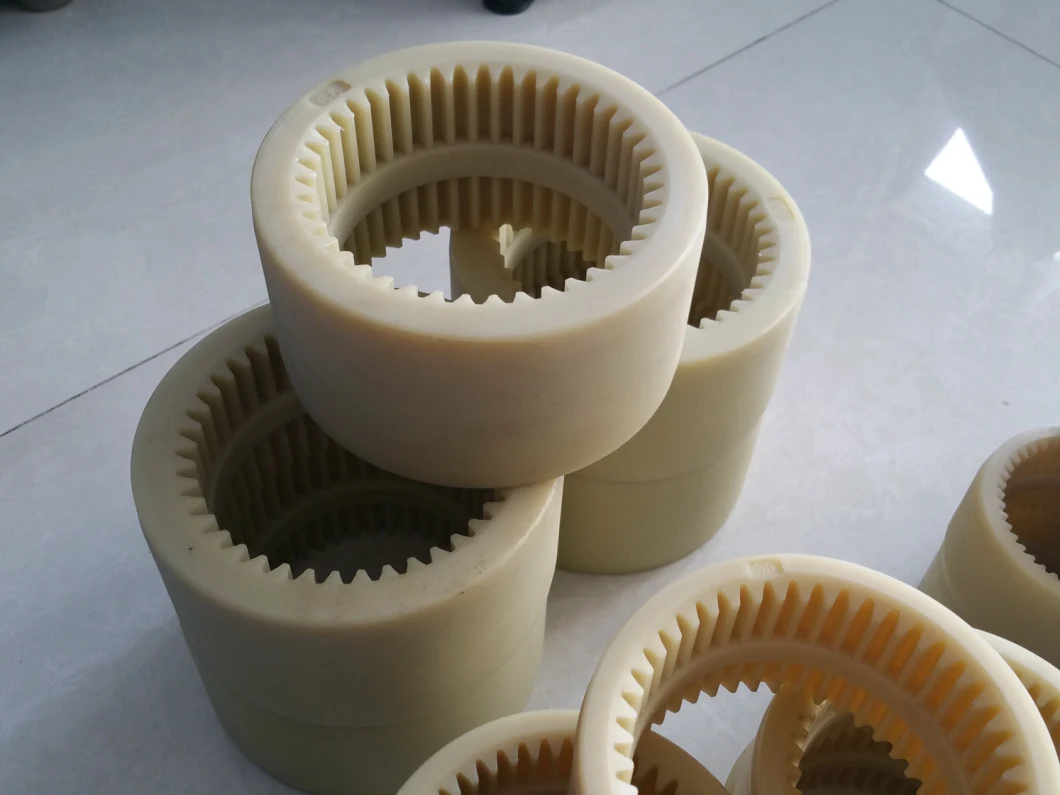

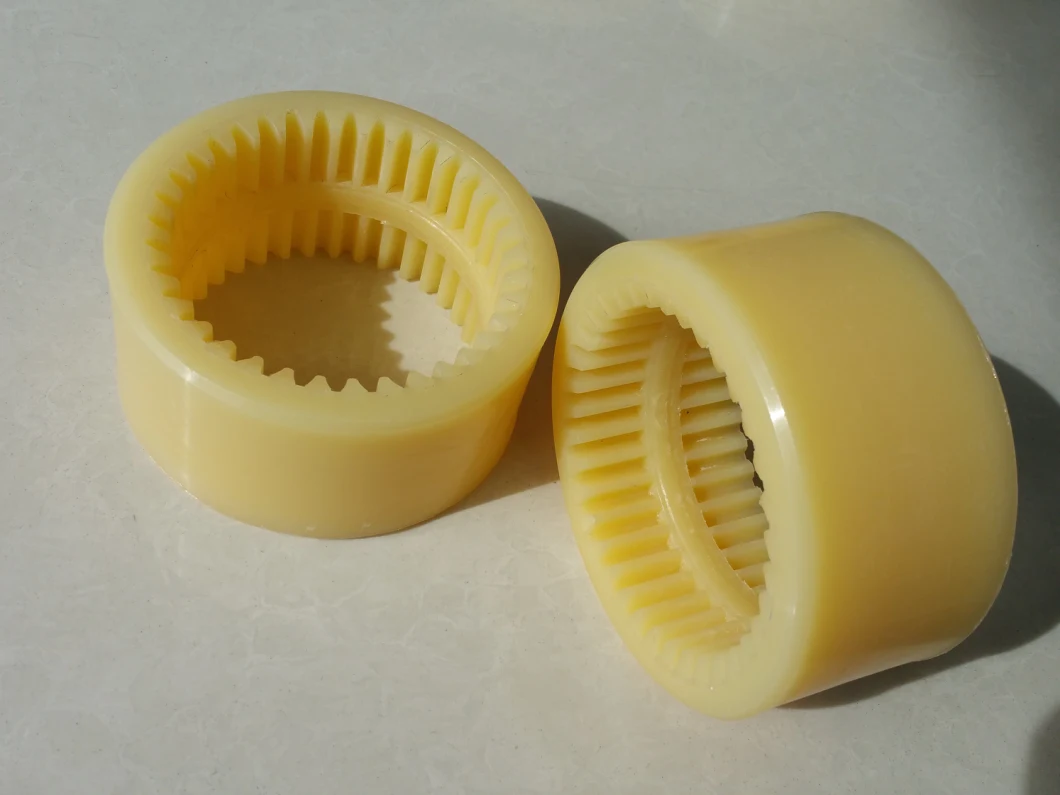

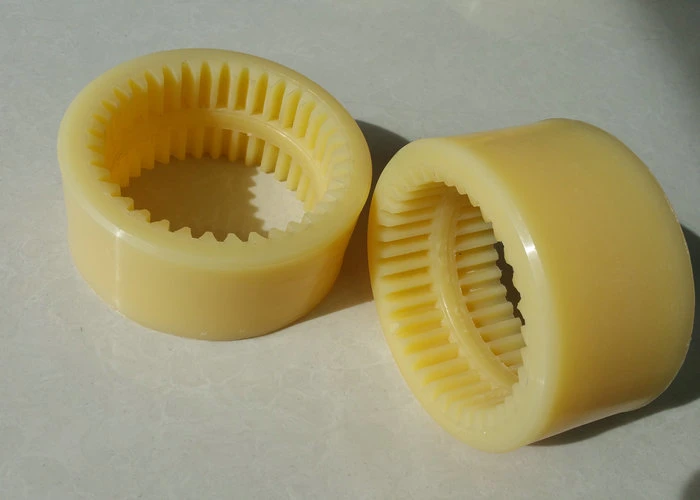

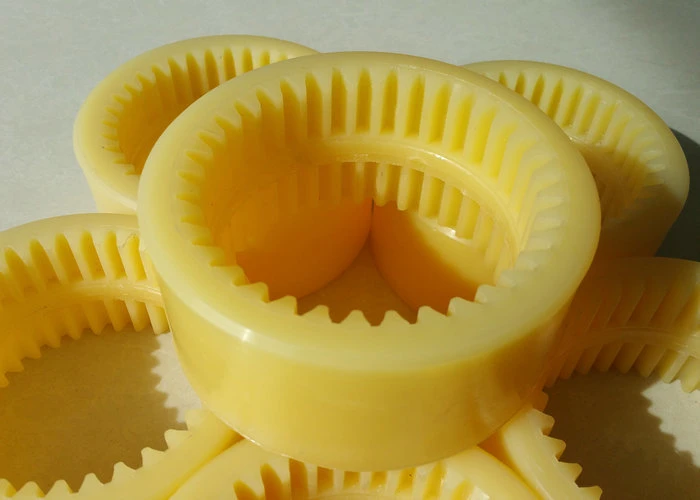

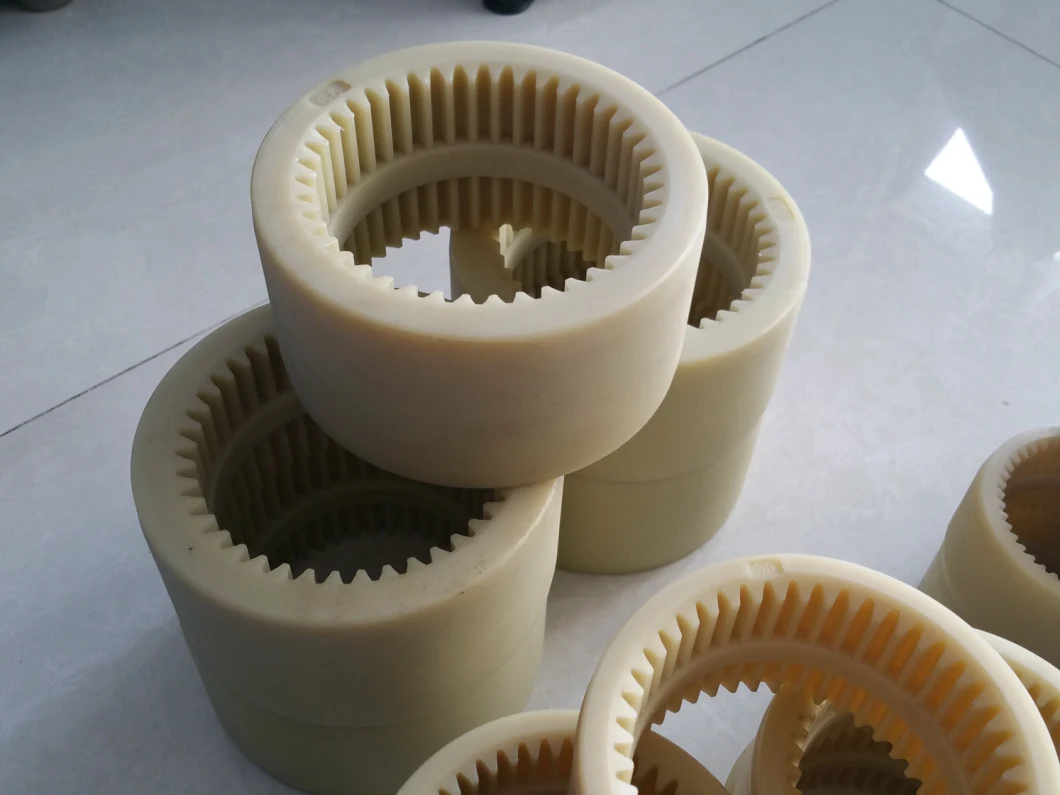

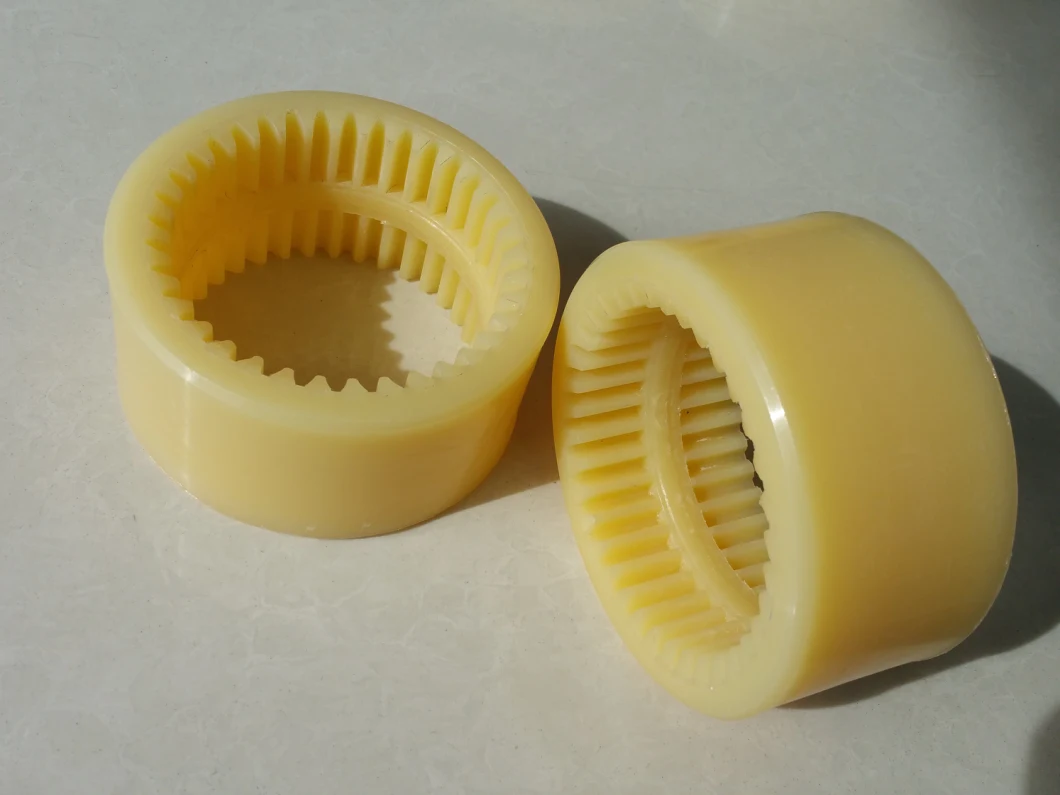

M14-65 Nylon Gear Coupling, Nylon Gear Sleeve for Flexible Shaft Connections (3A2006)

Curved-tooth Coupling/Coupling Bowex

Nylon sleeve coupling flexible shaft connections for a positive torque transmission and specifically suitable to compensate for axial, radial and angular shaft misalignment.

Nylon sleeve couplings are compact and require no lubrication. They are adapted to many applications including vertical and blind installations. They operate over a wide range of temperature at speed up to 5000RPM. This type of coupling is widely used in application such as motor, generator and pump etc.

Features:

Nylon-steel combined

Maintenance free

Compensation for axial, radial and angular misalignment

Convenient axial plugging assembly

Without bolts, pins, flanges to affect balance or safety

No requirement of lubrication

Excellent electrical insulation

Can be vertically or horizontally assembled

Tolerance of finished bore in appliance with ISOH7

Model No. M14, M19, M24, M28, M32, M38, M42, M48, M55, M65

Application: Industry

Material: Nylon

Hardness: Soft Tooth Surface

Manipulate Way: Forced Manipulation

Manufacturing Method: Rolling Gear

Toothed Portion Shape: Curved Gear

Changes Way: Stepped

Type: Circular Gear

Packing: in Fumigated Wooden Cases.

Specification: M14, 19, 24, 28, 32, 38, 42, 48, 55, 65

Origin: China

Nylon Sleeve and Steel combined: No Requirement of Lubrication

Excellent Electrical Insulation: Vertically or Horizontally Assembled

HS Code: 8483900000

Production Capacity: 50000pieces/month

Curved-tooth Coupling/Coupling Bowex

Nylon sleeve coupling flexible shaft connections for a positive torque transmission and specifically suitable to compensate for axial, radial and angular shaft misalignment.

Nylon sleeve couplings are compact and require no lubrication. They are adapted to many applications including vertical and blind installations. They operate over a wide range of temperature at speed up to 5000RPM. This type of coupling is widely used in application such as motor, generator and pump etc.

Features:

Nylon-steel combined

Maintenance free

Compensation for axial, radial and angular misalignment

Convenient axial plugging assembly

Without bolts, pins, flanges to affect balance or safety

No requirement of lubrication

Excellent electrical insulation

Can be vertically or horizontally assembled

Tolerance of finished bore in appliance with ISOH7

Model No. M14, M19, M24, M28, M32, M38, M42, M48, M55, M65

Application: Industry

Material: Nylon

Hardness: Soft Tooth Surface

Manipulate Way: Forced Manipulation

Manufacturing Method: Rolling Gear

Toothed Portion Shape: Curved Gear

Changes Way: Stepped

Type: Circular Gear

Packing: in Fumigated Wooden Cases.

Specification: M14, 19, 24, 28, 32, 38, 42, 48, 55, 65

Origin: China

Nylon Sleeve and Steel combined: No Requirement of Lubrication

Excellent Electrical Insulation: Vertically or Horizontally Assembled

HS Code: 8483900000

Production Capacity: 50000pieces/month

| Coupling No. | Item No. | Finished bore range | Outside Diameter | Nominal Torque Nm |

| M14 | UTNL-14-L | 6-14 | 40 | 10 |

| M19 | UTNL-19-L | 8-19 | 48 | 16 |

| M24 | UTNL-24-L | 10-24 | 52 | 20 |

| M28 | UTNL-28-L | 10-28 | 66 | 45 |

| M32 | UTNL-32-L | 12-32 | 76 | 60 |

| M38 | UTNL-38-L | 14-38 | 83 | 80 |

| M42 | UTNL-42-L | 20-42 | 95 | 100 |

| M48 | UTNL-48-L | 20-48 | 114 | 140 |

| M55 | UTNL-55-L | 25-55 | 132 | 240 |

| M65 | UTNL-65-L | 25-65 | 175 | 380 |